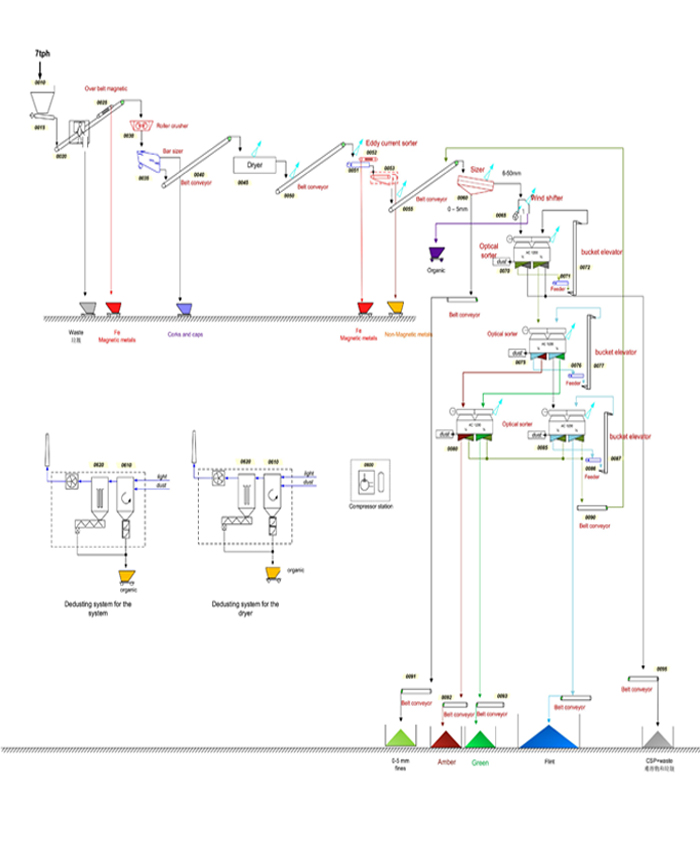

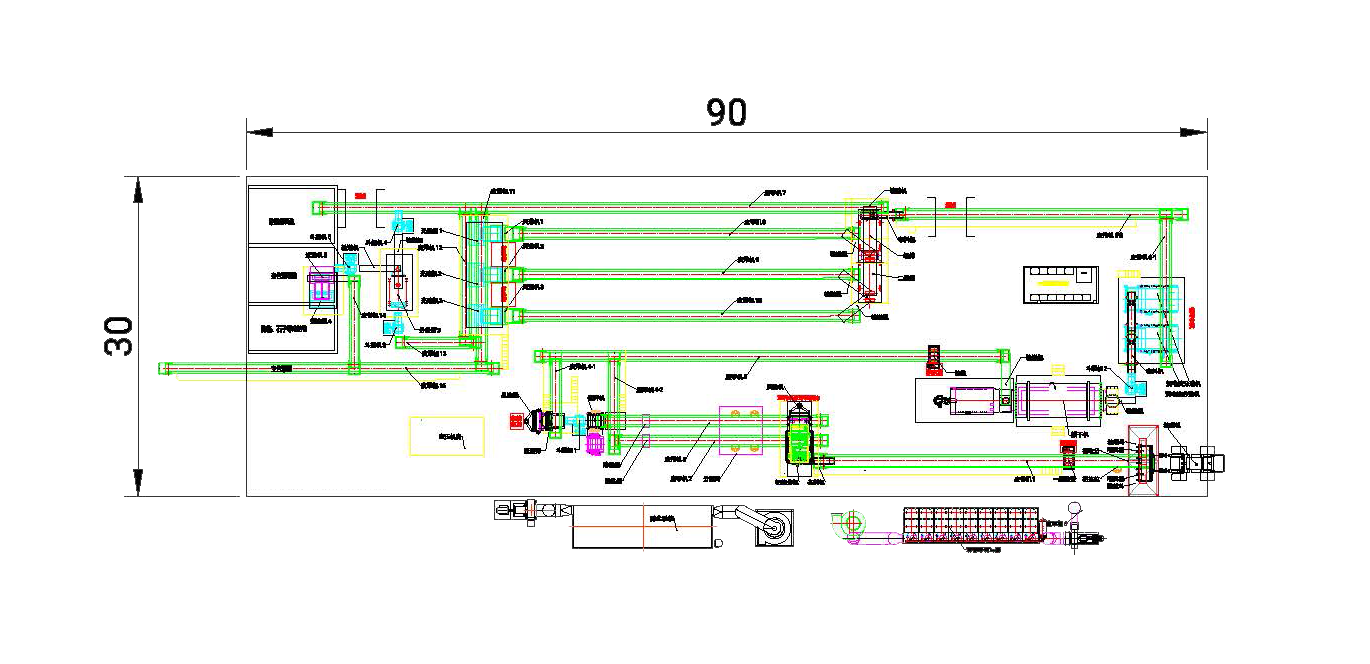

We take great pride in introducing our semi-dry sorting project within our turnkey engineering, representing the pinnacle of sorting technology. The semi-dry sorting project offers a cost-effective solution for processing glass raw materials with particle sizes greater than 8 millimeters and moisture content less than 4%.

The equipment is lined with wear-resistant alloy steel

Hammer tooth wear-resistant alloy coating

The bearing adopts Ha, watt and Luo bearings

The drive adopts domestic well-known brand reducer such as Tailong and Guomao

The sizer machine adopts bar + steel mesh design.

The bar is made of high-quality spring steel

The side plate and discharge port of the screening machine are designed with wear-resistant alloy

Steel mesh with chain knock anti-blockage

The wear part of the winnowing machine adopts wear-resistant alloy wear-resistant design

Adjustable orientation nozzle

Equipped with centrifugal fan

The bearing adopts Ha, watt and Luo bearings

With self-cleaning actuator

Type I spreader included

The bearing adopts Ha, watt and Luo bearings

The drive adopts domestic well-known brand reducer such as Tailong and Guomao

The sizer machine adopts a stepped bar design

The bar is made of high-quality spring steel

The side plate and discharge port of the screening machine are designed with wear-resistant alloy

Shock-absorbing mounts are standard

The fuel is natural gas.

Adopt three-return energy-saving dryer

The dryer is made of manganese steel, the thickness of the middle cylinder, inner cylinder and blade is 16mm, and the outer cylinder of the structure is 18mm

Including cyclone dust removal system and bag dust removal system